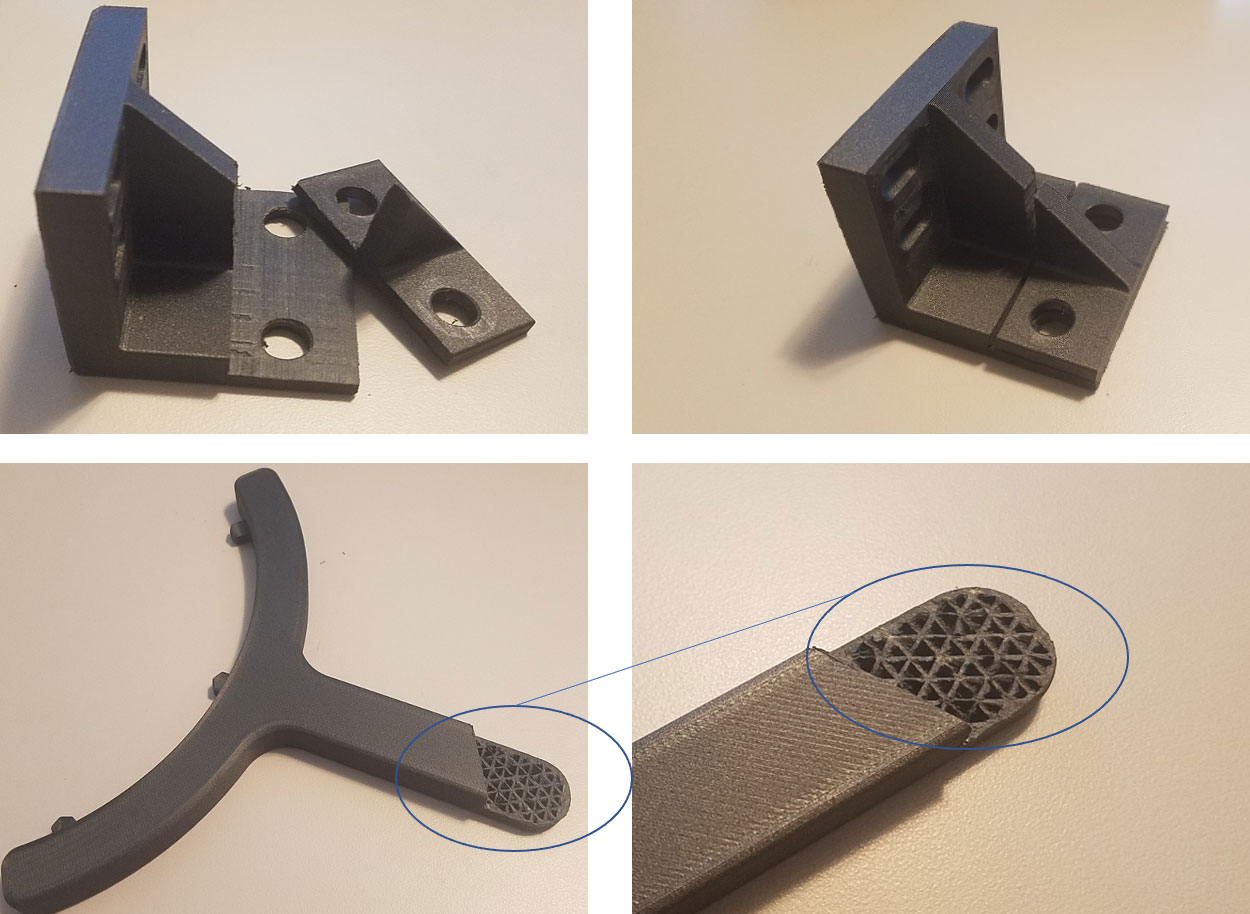

3-D Printing

Additive marketing which involves 3D printing in a number of creative ways to serve the needs of our customers. This can include low volume, prototypes or jigs and toolings. Contact us today so see what we can do for you.

Benefits of 3-D printing

- Can reach strengths of alum.

- Days instead of weeks

- Can be machined

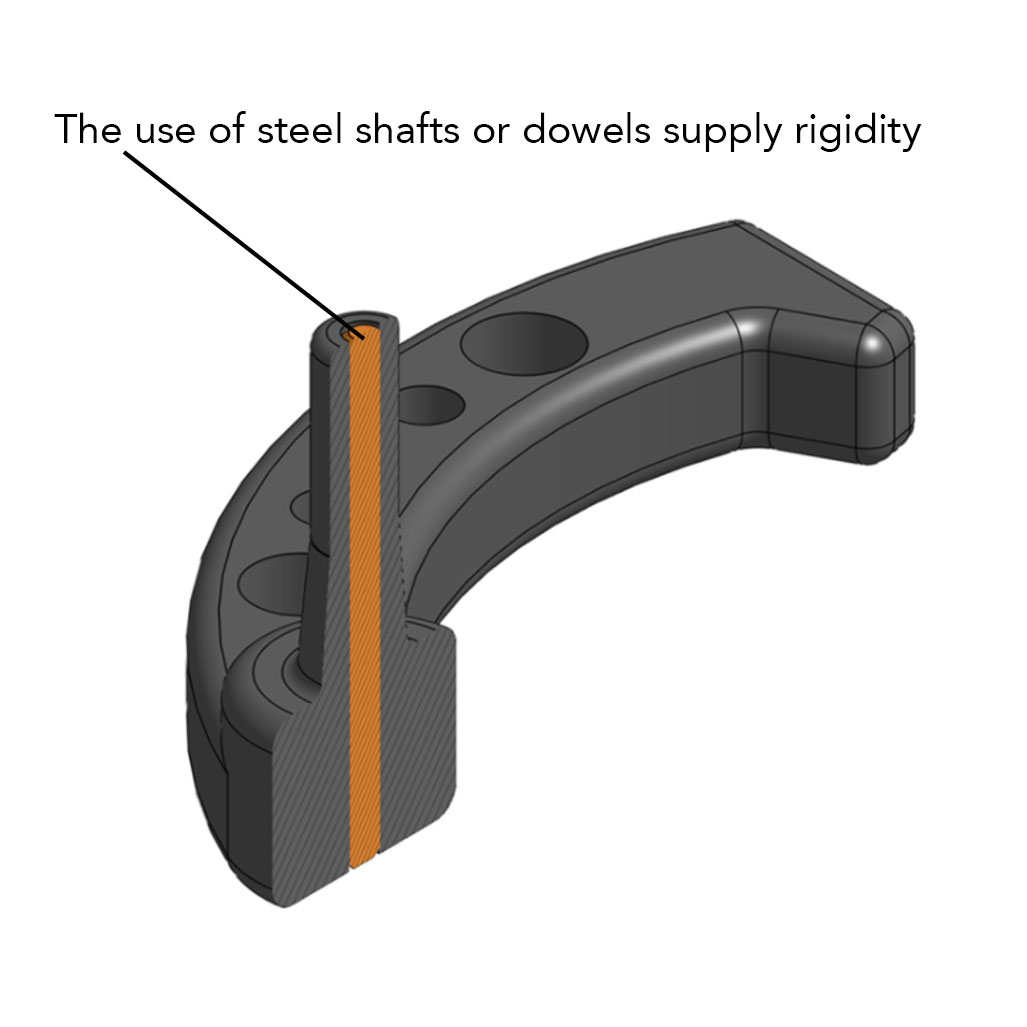

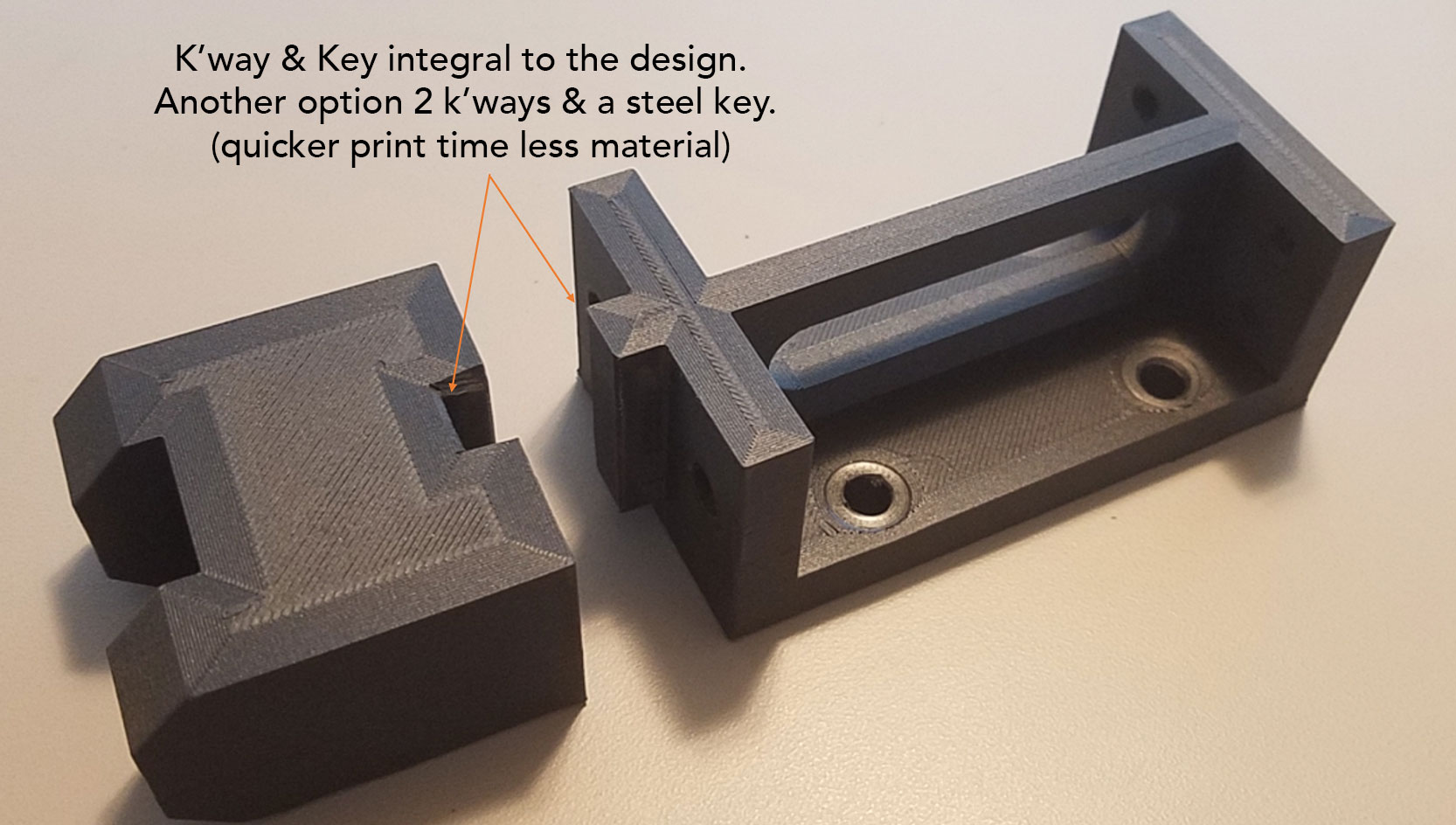

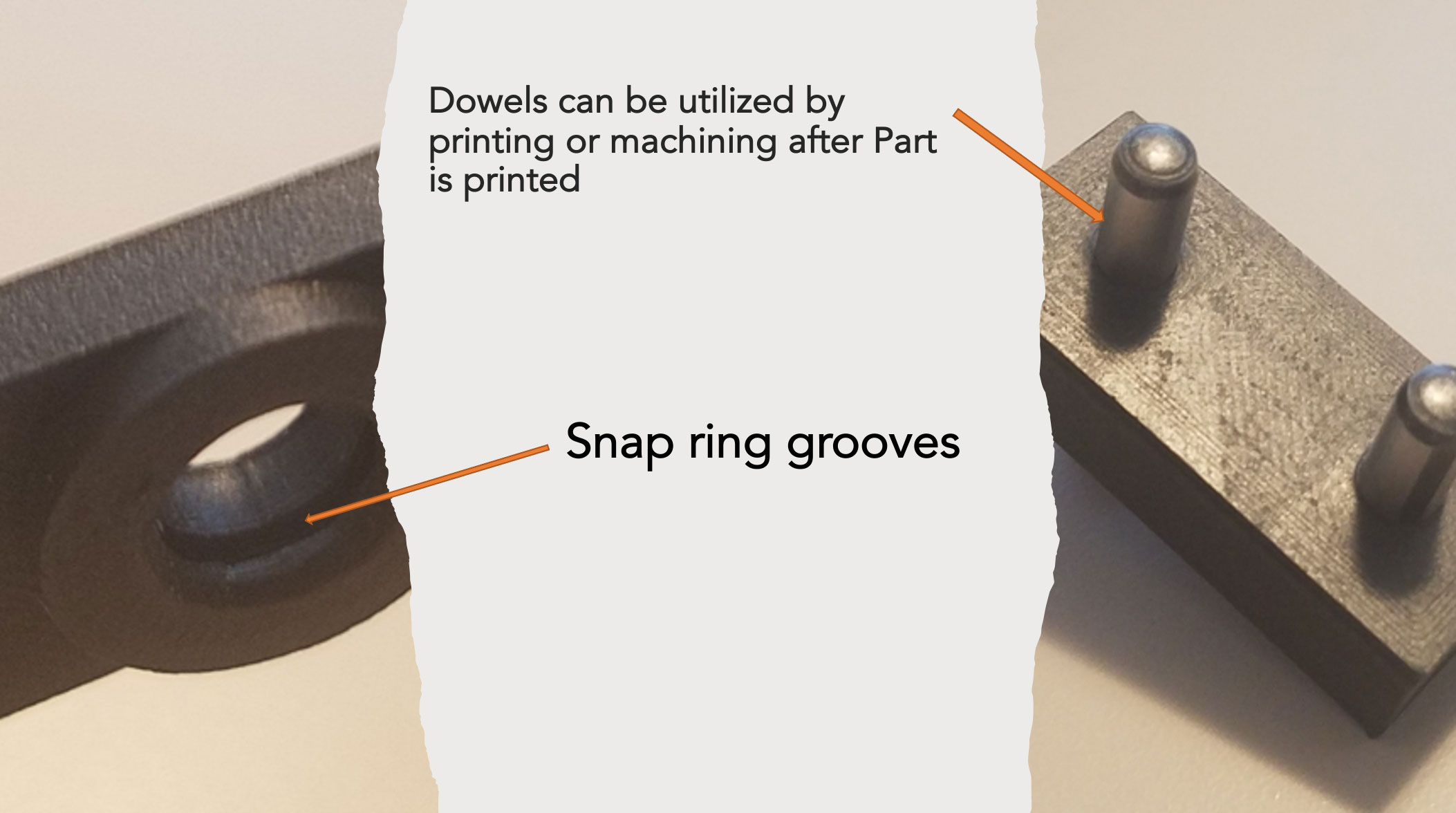

- Positive locating with dowels, keyways, etc.

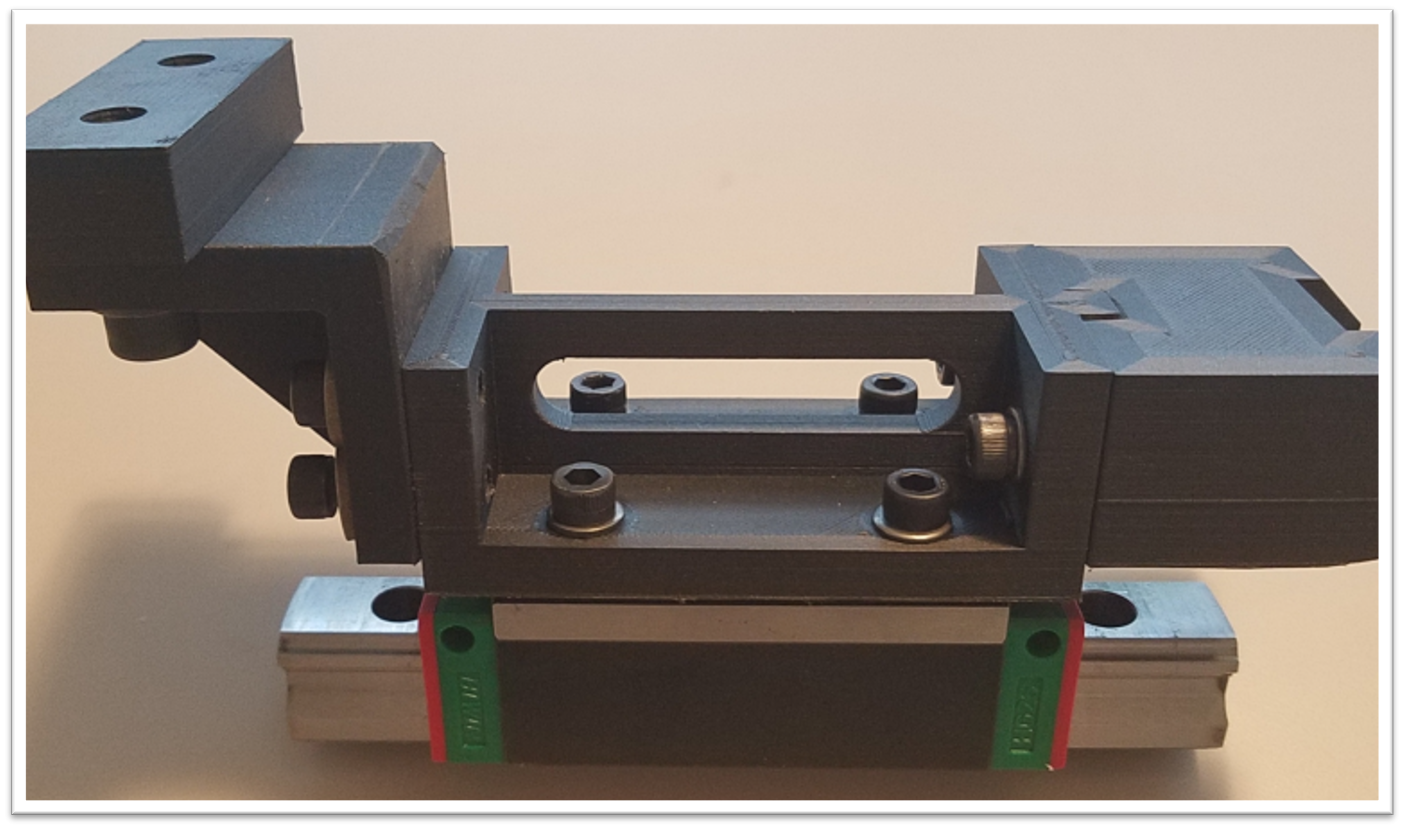

- Prove out assemblies

- Lighter EOAT assemblies

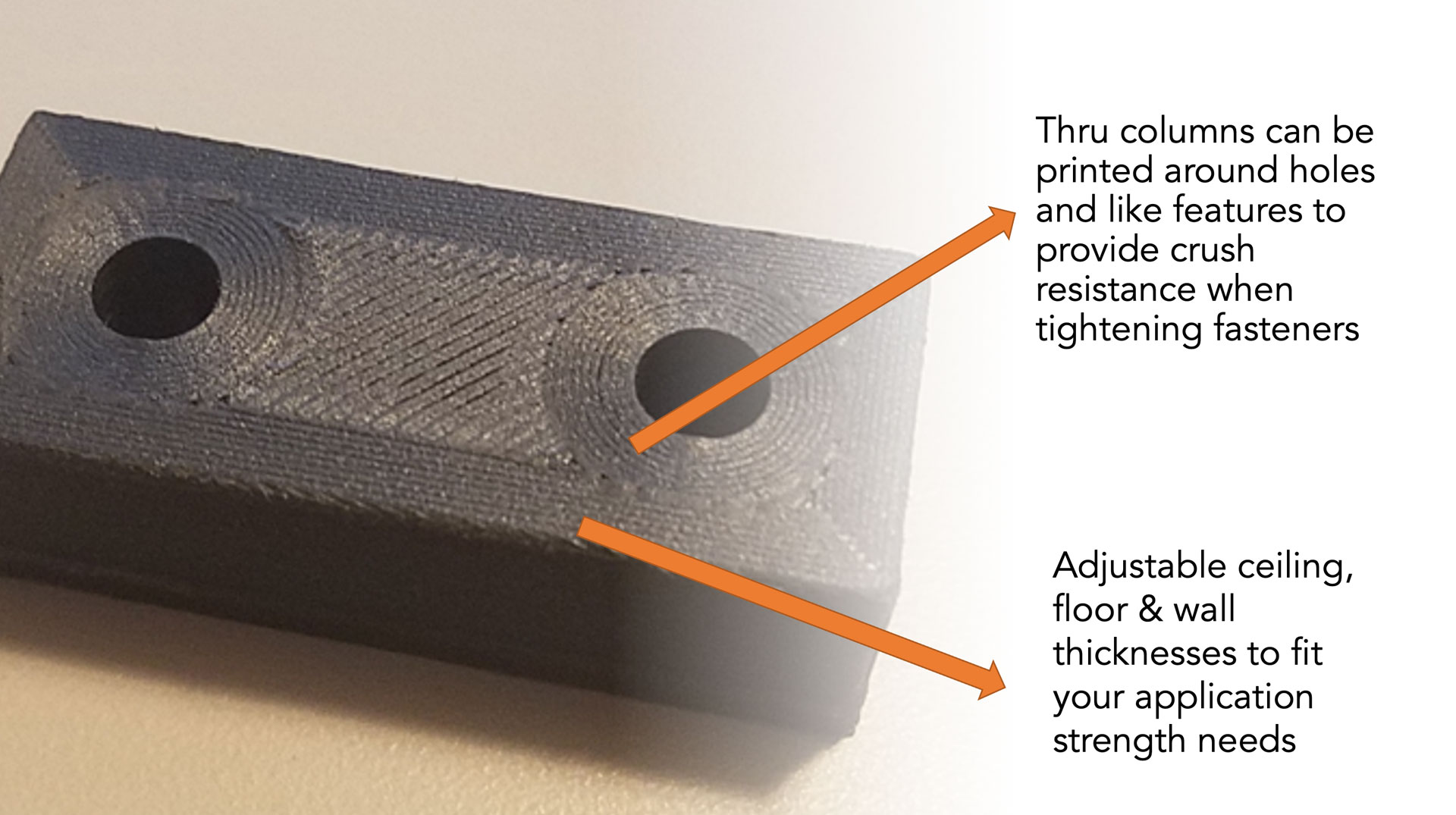

- Standard printing materials like Onyx contains chopped strands carbon fibers.

- Continuous strands of carbon fiber, Kevlar, Fiberglass or HSHT Fiberglass can Be added in-between standard printing material to strengthen areas of stress.

Application

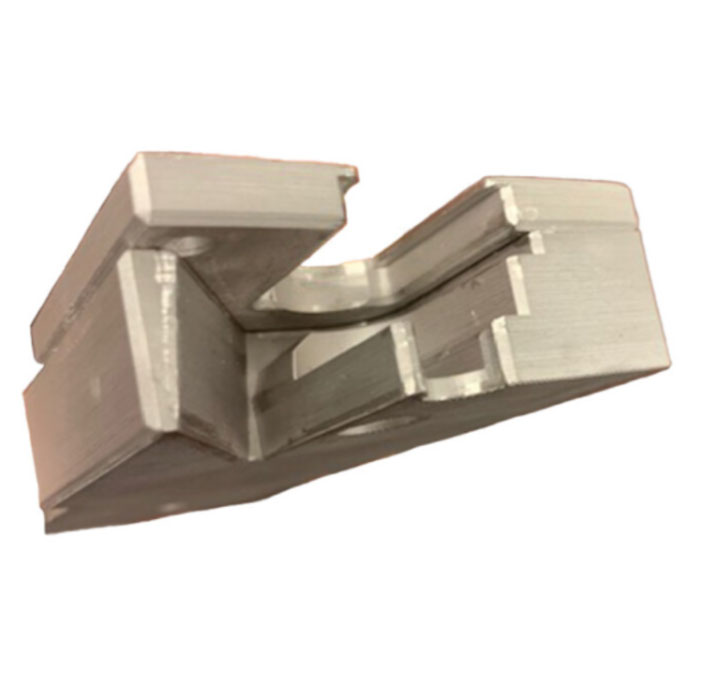

- Quickly & inexpensively prove out high dollar details or assemblies before releasing for machine.

- Rapid prototyping (days instead of weeks)

- Replacement parts

- Low volume part runs

- Corrosion resistant parts

- Wear-resistant inserts

- Paintable

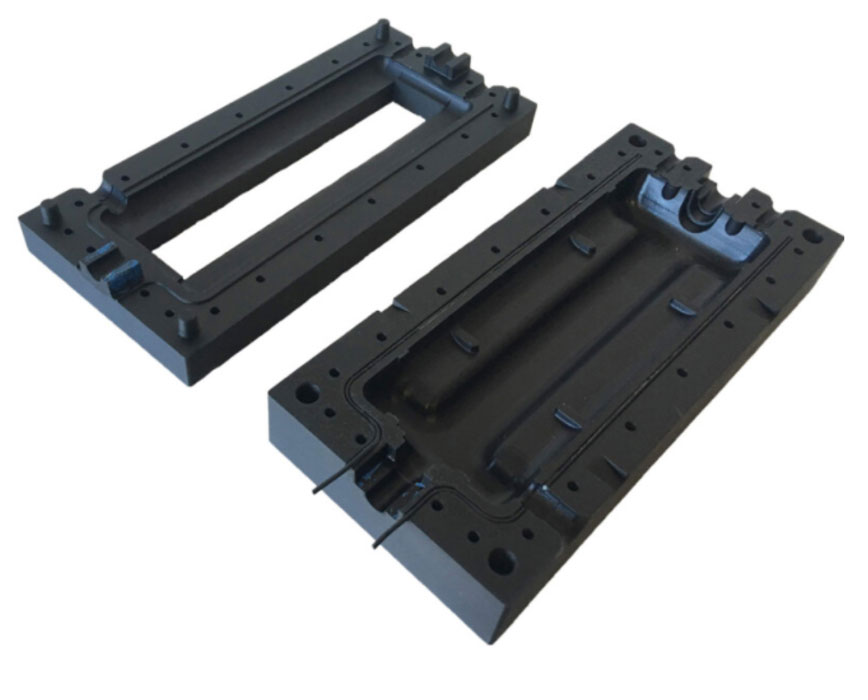

- Forming tooling

- Dies & punches

- EOAT’s

- Gripper fingers

- Inspection fixtures

- Entire assemblies

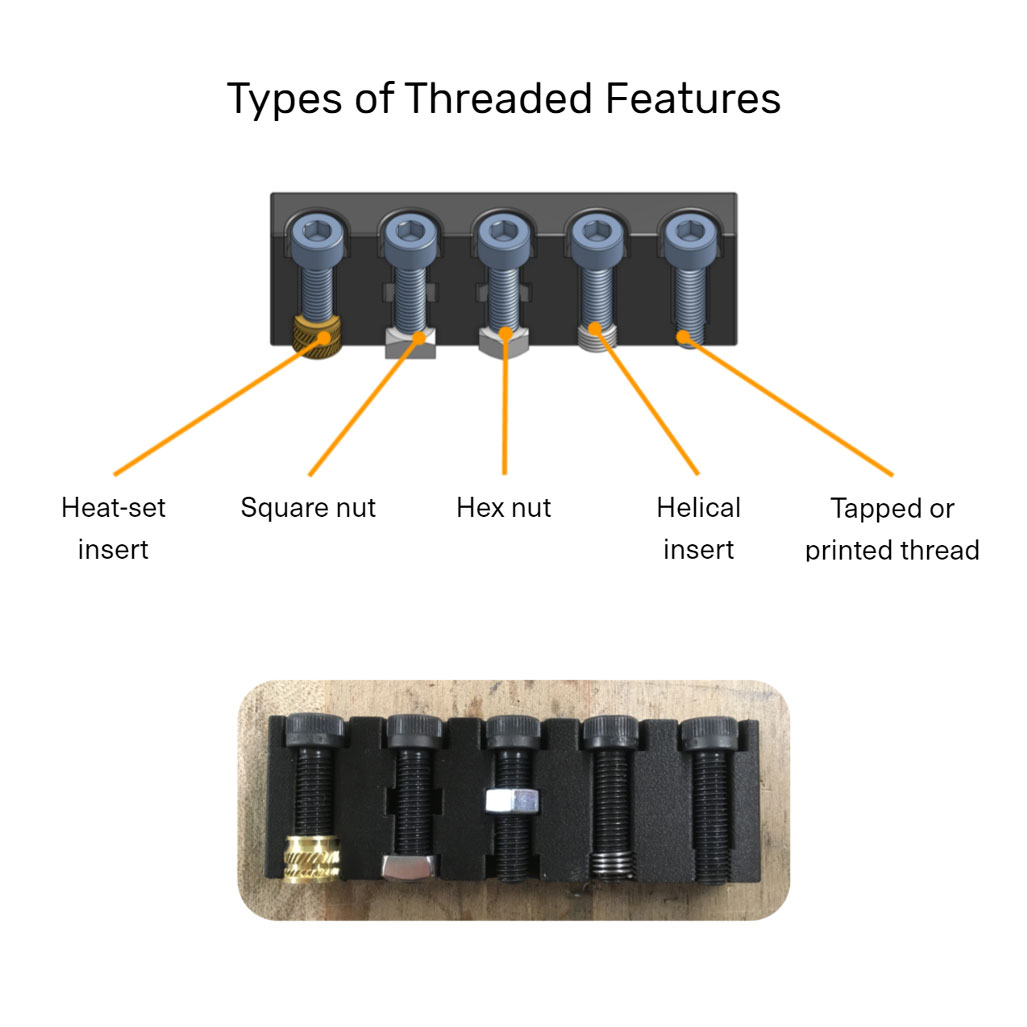

- Incorporate off the shelf purchase items

Composite Base

- OnyxTM

- Onyx FRTM

- Onyx ESDTM

- Nylon

Composite Base

- Carbon Fiber

- Carbon Fiber FR

- Aramid Fiber (Kevlar®)

- HSHT Fiberglass

- Fiberglass

Metal

- 17-4 PH Stainless Steel

- Copper

- Inconel 625

- H13 Tool Steel

A2 and D2 Tool Steel

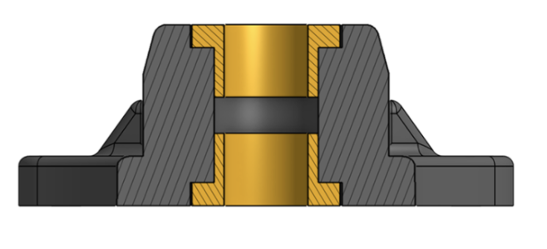

Sleeve Bearings/Bushing

Off the shelf carbide or steel inserts

That bolt, thread, or press into a printed part.

Isolate high hardness/grip strength

Properties to specific areas

Heat Set Inserts

Easily melted into a part with an expensive soldering iron and a correctly sized installation tip

High pull-out strength, when installed on opposite side of part as bolt

Entire Assemblies

Solid core for strength

Or a structural infill that still provides an

extremely strong & light part